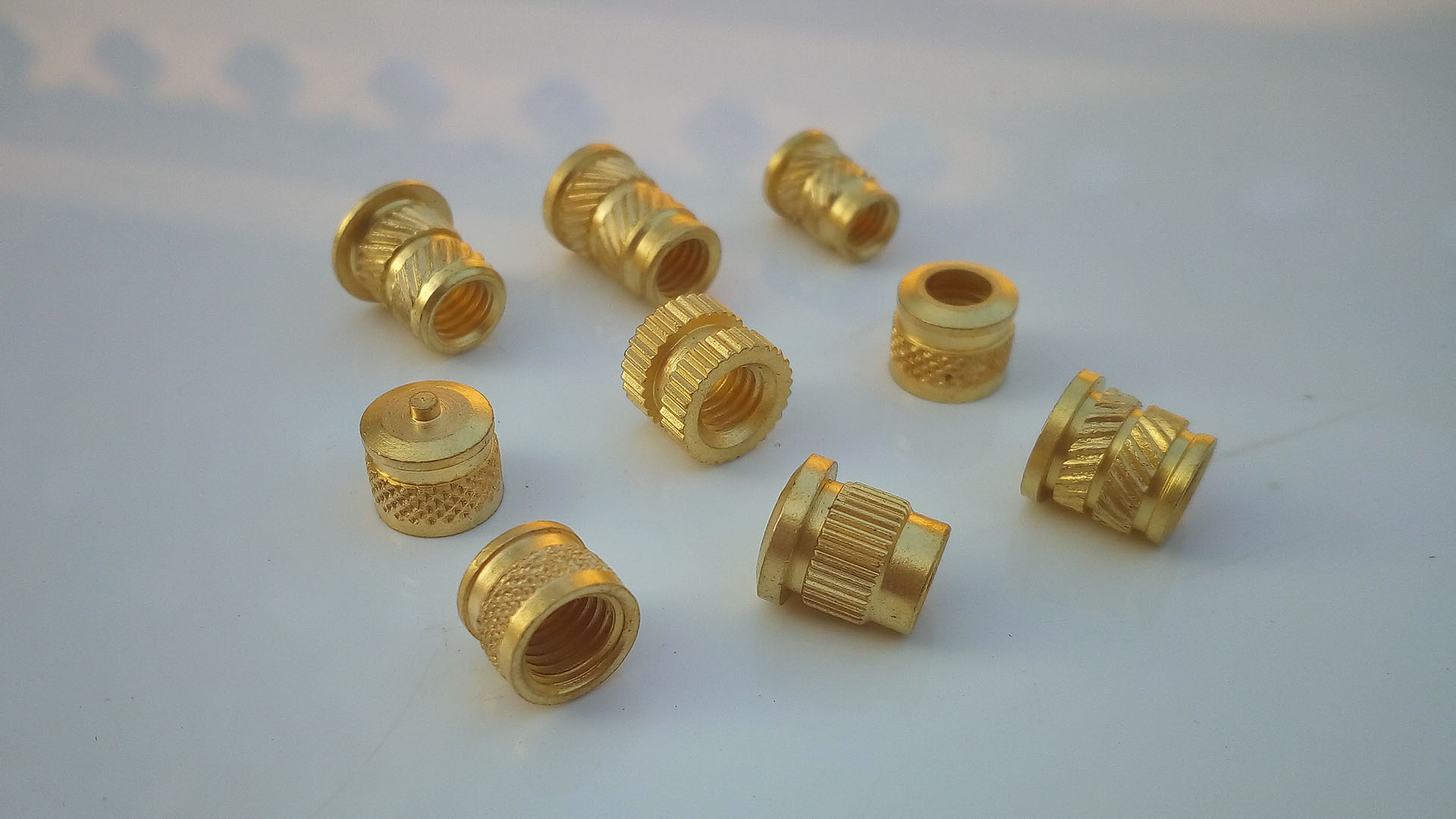

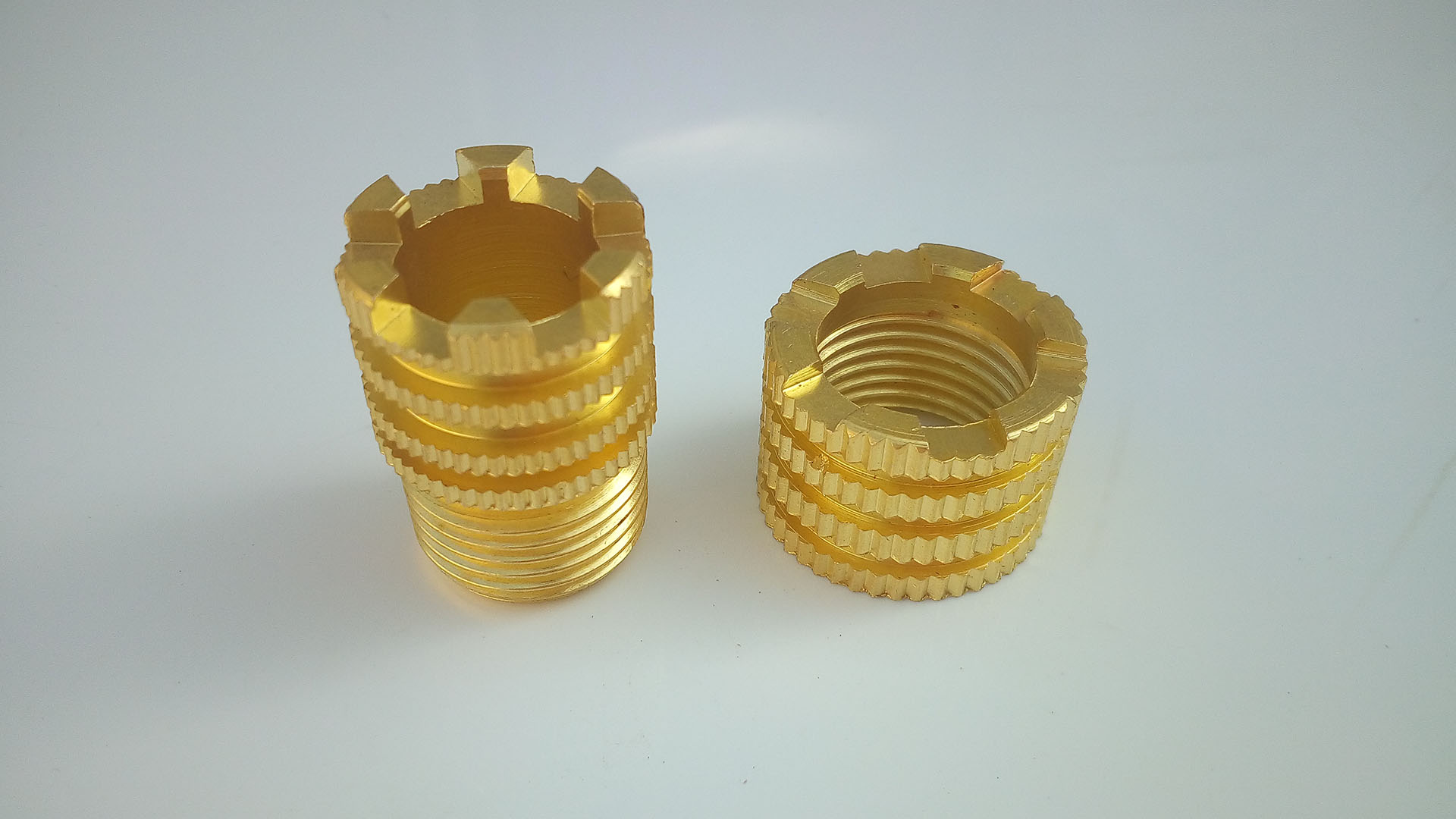

M3 Brass Inserts

M3 brass inserts play a crucial role in various industries. They create strong and dependable connections for a wide range of applications despite their small size. Whether you’re a DIY enthusiast or a professional engineer, understanding how to use M3 inserts effectively can significantly improve the quality and longevity of your projects.

Advantages of M3 Brass Inserts

- Enhanced Strength: Brass is known for its excellent strength and durability, providing a secure connection that can withstand substantial loads.

- Corrosion Resistance: Brass is highly resistant to corrosion, making M3 inserts suitable for both indoor and outdoor applications.

- Ease of Installation: These inserts are relatively easy to install, either by heat insertion or ultrasonic methods, ensuring a hassle-free assembly process.

- Versatility: M3 inserts can be used with various materials, including plastics, wood, and metals, making them versatile for different applications.

Applications of M3 Brass Inserts

- Electronics: Often, electronic component assemblies use M3 inserts, offering a dependable and secure fastening solution for circuit boards and enclosures.

- Plastics: They are commonly used in plastic parts, such as injection-molded cases and panels, to create threaded holes for screws and bolts.

- Furniture: M3 inserts are popular in the furniture industry for joining wooden parts, ensuring a sturdy and long-lasting connection.

- Automotive: These inserts secure various components, such as interior trim panels and dashboard components, in automotive applications.

- Aerospace: Aerospace engineers use M3 inserts to securely fasten critical components needing strong connections.

Our Brass Products:

- Terminals and Connectors

- Threaded Inserts

- Pin & Sockets

- Fasteners

- Pipes & Brass Tubes

- Switch Parts

- Fittings and Sanitary Parts

- Battery Terminals

- Forged Components

- Sheet Metal Components

- Machined Brass Components

- CNC Turned Parts

- Core Vents

For more details, you can Contact Us.

We are waiting for your call!

Please visit our official Instagram Page for updates from us.

Also, take a look at our Company’s profile.